What is Radiographic Testing ?

PRINCIPLE

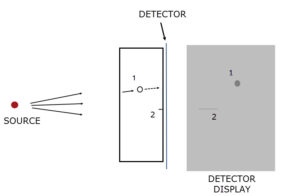

Radiography is based on the electromagnetic radiation that transmits through a volume of material and is attenuated to different degrees depending on the amount of material loss. Radiography is a thru transmission method where the object is placed in between the radiation source and detector. A defect is a loss of material and therefore lesser attenuation and higher transmission. This difference in transmission is detected by the radiation sensitive detector that produces grey images where changes in density (darkness) are used to detect discontinuities.

EQUIPMENT

Basic equipment for radiography includes a radiation source, Image quality indicators (IQI), detector. Detector can be digital panel or film. Safety equipment required includes a GM counter, a dosimeter and TLD badges. Radiation sources can be either a X-Ray tube or a gamma ray source such as Iridium-192. Radiation energy used is in the range 50 KV to 1 MeV

RADIOGRAPHIC QUALITY

The following define radiographic quality

- Sensitivity. Ability to detect a 2% difference in thickness. This is verified by using image quality indicators (IQI), which are wires or shims with small holes

- Unsharpness. Placing source and film relative to object so that the penumbra of the image does not exceed 0.5 mm. For digital detectors, unsharpness is measured with duplex wire pair IQI.

- Density. The film should be gray and neither too white nor too black

Several variables go into making a good radiograph and these include the type of radiation source (X-rays or gamma ray), X-ray energy level, film grain size, exposure time, etc. Images produced using X-rays produce images with better contrast as compared to gamma rays.

APPLICATIONS

Radiography is a volumetric NDT technique and has a variety of applications primarily being weld inspections in piping and pressure vessels. Inspection is done either with the source placed inside the pipe/pressure vessel and the film outside, called single wall exposure technique, or by placing source and detector on the outside, called double wall exposure technique.

Radiography is extensively used in the aerospace industry for inspection of airframe structures. Digital RT is more common in aerospace industry.

INDUSTRY CODES

ASME V, Article 2

ISO 17636-1 Film Radiography

ISO 17636-2 Digital Radiography

TRAINING

- RT Level I, Course no – NDT-112

- Duration – 40 hours

- RT Level II, Course no – NDT-211

- Duration – 40 hours after completion of Level I